A garment marker maker with CAD software is an essential tool in the fashion industry. This specialized software allows designers and manufacturers to create accurate and efficient markers for cutting fabric patterns. With its advanced features, a garment marker maker can optimize the placement of pattern pieces on fabric rolls, minimizing waste and maximizing material utilization.

The CAD software offers precise measurement tools, allowing designers to customize markers according to the size and shape of their garments. Moreover, this technology enables easy adjustment of marker layouts to meet specific production requirements such as size variations or order quantities. By streamlining the marker-making process, this software significantly reduces production costs and time, increasing overall productivity for clothing manufacturers. Achieving precision and efficiency are fundamental aspects of producing high-quality garments, making a garment marker maker with CAD software an indispensable asset in today’s fashion industry.

The modern fashion industry operates in a fast-paced and highly competitive environment, where efficient production processes play a crucial role in achieving success. To meet the ever-changing demands of consumers and stay ahead of the competition, fashion manufacturers are constantly seeking ways to streamline their production processes. One area that has witnessed significant advancements in recent years is garment marker making, which involves the creation of markers for fabric cutting. With the integration of Computer-Aided Design (CAD) software, the garment marker-making process has been revolutionized, offering numerous benefits such as enhanced efficiency, accuracy, and cost-effectiveness.

Garment Marker Maker

This article aims to explore the role of CAD software in streamlining production processes in the fashion industry, specifically focusing on a garment marker maker. We will delve into the evolution of CAD software in fashion, the advantages it brings, key features and functionalities, successful case studies, challenges in adoption, and future trends in the field. By understanding the impact of CAD software on a garment marker maker, for fashion manufacturers can optimize their production processes and achieve greater success in the dynamic fashion market.

- Introduction: The importance of streamlining production processes in the modern fashion industry

1.1 The significance of efficient production processes in the fashion industry

Time is of great importance in the fast-paced fashion industry. With trends coming and going quicker than a cat chasing a laser pointer, fashion manufacturers need to be able to produce garments at lightning speed. That’s where streamlining production processes comes in.

Also Read: Elevating Fashion Industry: Cutting-Edge CAD Software for Garment Pattern Makers

Efficient production processes not only ensure that fashion brands stay ahead of the game but also have a direct impact on the bottom line. From reducing lead times to minimizing material waste, streamlining production is the key to staying competitive in the industry.

1.2 Challenges faced by fashion manufacturers in maintaining streamlined production

However, maintaining streamlined production is easier said than done. Fashion manufacturers face a plethora of challenges that can throw a wrench into the production process. From last-minute design changes to unpredictable demand fluctuations, it’s like trying to walk on a runway made of banana peels.

Also Read: Cutting-Edge Technology for Perfect Patterns: The CAD Garment Pattern Grading

To overcome these challenges, manufacturers need tools and technologies that can help them navigate the twists and turns of the fashion industry. One such tool is garment marker making with CAD software, which has revolutionized the way garments are produced.

- Understanding garment marker making: Definition and significance in fashion manufacturing

2.1 Definition and purpose of garment marker making

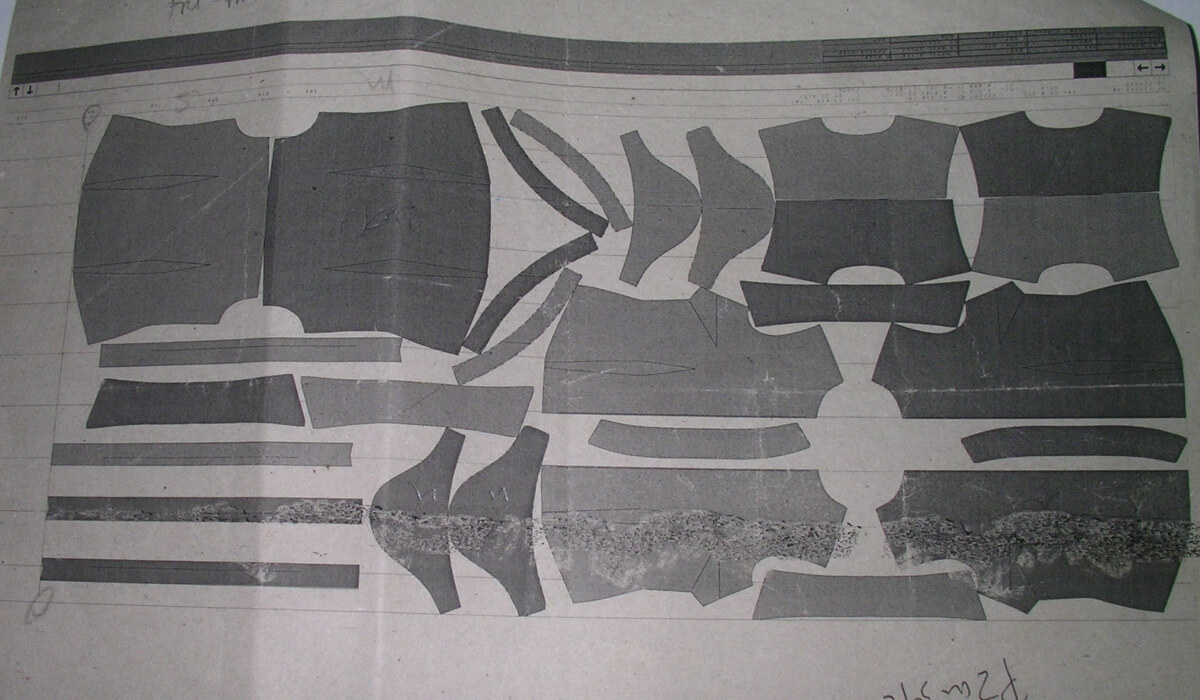

Garment marker making is the process of creating markers, which are essentially layouts of pattern pieces on fabric, to be used for cutting garment components. These markers determine how efficiently fabric is utilized, ensuring minimal waste and maximum yield.

Think of garment marker making as a puzzle, where each pattern piece is like a unique puzzle piece that needs to fit together perfectly. The goal is to arrange these pieces on the fabric in the most efficient way possible, like a fashion-forward game of Tetris.

2.2 The role of garment marker maker in optimizing material utilization

In the world of fashion, fabric is money. Every square inch of fabric wasted is like throwing dollar bills into a shredder. Garment marker maker plays a crucial role in optimizing material utilization by finding the most efficient arrangement of pattern pieces on the fabric.

By using CAD software, garment marker makes can create markers that minimize fabric waste, resulting in significant cost savings for manufacturers. It’s like getting a discount on fabric without even having to haggle with a salesperson.

3. Evolution of CAD software in fashion: Revolutionizing the garment marker-making process

3.1 Historical overview of CAD software adoption in fashion production

Back in the day, garment marker maker was a painstakingly manual process. Marker makers would spend countless hours meticulously arranging pattern pieces on paper, using more tape than a bandage factory. But then, CAD software came galloping in on its digital horse.

CAD software, short for Computer-Aided Design, revolutionized the fashion industry by introducing digital tools and automation. It replaced the protractor with precision, the paper with pixels, and the eraser with the magic undo button. Suddenly, garment marker making became faster, more accurate, and less likely to induce paper cuts.

3.2 Advancements and innovations in CAD software for a garment marker maker

With each passing year, CAD software for garment marker making has become more advanced than a fashionista’s sense of style. Features like automatic nesting, interactive marker editing, and real-time fabric simulation have made the process even more efficient and user-friendly.

Today, CAD software allows garment marker makers to create markers with a few clicks and drags, saving valuable time and reducing the risk of repetitive stress injuries from excessive tape usage. It’s like having a virtual assistant that knows exactly how to make every pattern piece work its runway magic.

4. Benefits of integrating CAD software in garment marker making: Efficiency, accuracy, and cost-effectiveness

4.1 Enhanced efficiency and productivity with CAD software

Integrating CAD software in garment marker making is like giving it a turbo boost. The efficiency gains are so significant that you’ll feel like your production process just ran a marathon on roller skates. With features like automatic nesting and marker optimization algorithms, CAD software can create markers in a fraction of the time it takes manually.

Not only does this save time, but it also frees up marker makers to focus on other important tasks, like sipping coffee and contemplating the meaning of life. It’s like having your assistant, except it’s a digital one that never asks for a raise.

4.2 Improved accuracy and precision in garment marker creation

When it comes to garment marker-making, precision is everything. One wrong move and the whole puzzle falls apart like a poorly constructed dress. Thankfully, CAD software brings a level of accuracy to the process that would make a mathematician proud.

With real-time fabric simulation and interactive marker editing, garment marker makers can see exactly how the pattern pieces will fit on the fabric before even making a single cut. It’s like having a crystal ball that predicts the future of your garment’s layout.

4.3 Key features and functionalities of CAD software for garment marker making

Last but not least, integrating CAD software in garment marker making has a direct impact on the financial health of fashion manufacturers. By optimizing material utilization and reducing fabric waste, CAD software helps cut costs and increase profitability.

With CAD software, manufacturers can squeeze every last drop of value out of their fabric, like a fashion-loving juicer. It’s like having a magic wand that turns waste into profit, and what could be more fashionable than that?

So, if you’re in the fashion industry and still using outdated manual methods for garment marker making, it’s time to join the digital revolution. Embrace the power of CAD software, streamline your production processes, and let your garments shine on the runway of success. After all, in fashion, time is money, and you don’t want to be fashionably late to the profit party.

5. Key features and functionalities of CAD software for garment marker making

5.1 Digitized pattern drafting and manipulation

Gone are the days of manual pattern drafting on paper. CAD software revolutionizes this process by allowing designers to create and manipulate patterns digitally. This feature not only saves time but also enables greater accuracy and precision.

5.2 Automatic nesting and material utilization optimization

With CAD software, the days of playing Tetris with fabric pieces are over. The software automatically arranges pattern pieces on the fabric to minimize waste and maximize material utilization. This not only saves costs but also reduces the environmental impact of fashion production.

5.3 Simulations and Virtual Prototyping Capabilities

CAD software brings virtual prototyping to the fashion industry, allowing designers to visualize garment construction and fit without the need for physical samples. Simulations enable quick adjustments and modifications, reducing the time and resources needed for multiple physical iterations.

6. Case studies: Successful implementation of CAD software in fashion production

6.1 Case study 1: How XYZ Fashion Company improved production efficiency with CAD software

XYZ Fashion Company saw a significant boost in efficiency after implementing CAD software for garment marker making. By automating marker creation and optimizing material utilization, they reduced production time while increasing output. The software also facilitated collaboration between designers and manufacturers, streamlining communication and reducing errors.

6.2 Case study 2: The impact of CAD software on material waste reduction at ABC Fashion Brand

ABC Fashion Brand experienced a remarkable reduction in material waste through the adoption of CAD software. The automatic nesting feature allowed them to use every inch of fabric efficiently, minimizing scraps and remnants. This not only reduced their environmental footprint but also translated into significant cost savings.

7. Overcoming challenges and considerations for adopting CAD software by a garment marker maker

7.1 Integration challenges and potential resistance from traditional production processes

Integrating CAD software into existing production processes can be a challenge, especially if there is resistance from traditional methods. It is crucial to address any concerns and provide training and support to ensure a smooth transition.

7.2 Training and skill development for CAD software utilization

Utilizing CAD software requires training and skill development for designers and production teams. Investing in proper training programs and providing continuous support is essential to maximize the benefits of the software.

7.3 Cost considerations and return on investment analysis

While CAD software offers numerous advantages, it is important to carefully evaluate the costs and potential return on investment. Factors such as software licensing, hardware requirements, and ongoing maintenance should be considered before implementation.

8. Future trends and advancements by a garment marker maker with CAD software

As technology continues to evolve, so does the potential for garment marker-making with CAD software. Advancements in artificial intelligence and machine learning may further optimize material utilization and streamline production processes. Additionally, the integration of virtual reality and augmented reality may enhance the virtual prototyping capabilities, allowing designers and manufacturers to collaborate in a more immersive and interactive manner. The future of garment marker making is undoubtedly exciting, and CAD software will play a significant role in shaping it.

2 Rolls 36″ x 300′ 20 lb Bond 2″ Core Wide Format Inkjet CAD Plotter Paper

In conclusion, the integration of CAD software in garment marker making has emerged as a game-changer in the modern fashion industry. The benefits of enhanced efficiency, accuracy, and cost-effectiveness offer tremendous opportunities for fashion manufacturers to streamline their production processes. By leveraging the key features and functionalities of CAD software, fashion brands can optimize material utilization, reduce waste, and improve overall productivity. Despite the challenges and considerations associated with adopting CAD software, its immense potential for transforming the garment marker-making process cannot be ignored. Looking ahead, as technology continues to advance, we can expect further innovations and advancements in garment marker-making with CAD software. By staying abreast of these developments, fashion manufacturers can continue to evolve and thrive in an increasingly competitive industry.

FAQ:

- What is garment marker making and why is it important in fashion manufacturing?

Garment marker making is the process of creating markers, which are templates used for cutting fabric in fashion manufacturing. It is a critical step in optimizing material utilization and reducing waste in production. By efficiently arranging pattern pieces on fabric, garment marker making helps maximize productivity and minimize costs for fashion manufacturers. - How does CAD software revolutionize the garment marker-making process?

CAD software revolutionizes the garment marker-making process by offering digitized pattern drafting, manipulation, and automatic nesting capabilities. With CAD software, fashion designers and manufacturers can create, modify, and optimize markers digitally, resulting in improved efficiency, accuracy, and cost-effectiveness. CAD software enables virtual prototyping and simulations, allowing for quick adjustments and minimizing errors before the actual cutting process begins. - What are the benefits of integrating CAD software in garment marker making?

Integrating CAD software in garment marker-making offers several benefits. Firstly, it enhances efficiency and productivity by automating the marker creation process, saving time and effort. Secondly, it improves accuracy and precision in marker development, reducing the chances of errors and minimizing fabric waste. Lastly, it enables cost-effectiveness by optimizing material utilization, reducing fabric waste, and ultimately lowering production costs. - What challenges should fashion manufacturers consider when adopting CAD software in garment marker making?

When adopting CAD software in garment marker making, fashion manufacturers should consider challenges such as integration difficulties with existing production processes, potential resistance from traditional practices, and the need for training and skill development. Additionally, cost considerations and return on investment analysis should be taken into account to evaluate the financial feasibility of implementing CAD software in garment marker making.

Leave a Reply