In this article, we will delve into the world of CAD garment pattern grading, exploring its benefits, key features, industry applications, and future trends, to understand how this innovation is reshaping the fashion industry.

Pattern grading plays a crucial role in the fashion industry, ensuring that garments are available in a range of sizes to fit diverse body types. Traditionally, pattern grading was a labor-intensive and time-consuming process, but with the advent of cutting-edge technology, such as Computer-Aided Design (CAD), the landscape of pattern grading has been revolutionized. CAD technology has brought unprecedented efficiency, accuracy, and flexibility to the pattern grading process, enabling fashion designers and manufacturers to achieve perfect patterns effortlessly.

1. Introduction: The Importance of Garment Pattern Grading

1.1 The Role of Pattern Grading in the Fashion Industry

Picture this: You’ve found the perfect dress online, it looks fabulous on the model, and you can’t wait to order it. But when it arrives, it doesn’t quite fit as perfectly as you had hoped. Frustrating, right?

Well, here’s where garment pattern grading comes in. It’s the behind-the-scenes magic that ensures your clothes fit you well, regardless of your size or shape. Pattern grading involves scaling a base pattern up or down, proportionately, to create different sizes of a garment. It’s like those Russian nesting dolls, but for fashion.

2. Understanding CAD (Computer-Aided Design) Technology

2.1 Definition and Overview of CAD Technology

As technology continues to revolutionize various industries, it’s no surprise that the fashion world has also jumped on the digital bandwagon. Enter Computer-Aided Design (CAD) technology. CAD is a fancy term for using computers to create, modify, and optimize designs. Think of it as a fashion designer’s high-tech secret weapon.

Also Read: Innovation at its Finest: Exploring the World of CAD Plotters and its Impact on Design

2.2 Evolution and Adoption of CAD in the Fashion Industry

CAD technology has come a long way since its humble beginnings. Initially used primarily in the fields of architecture and engineering, it has now found its place in the fashion industry. Designers can now easily sketch their ideas on a computer, manipulate patterns digitally, and bring their creations to life with a few clicks.

3. The Role of CAD in Garment Pattern Grading

3.1 How CAD Enhances Efficiency and Accuracy in Pattern Grading

Thanks to CAD technology, garment pattern grading has become faster, more accurate, and a lot less tedious. With traditional manual grading, designers had to meticulously measure and grade patterns by hand, which was a time-consuming and error-prone process. CAD software automates this process, allowing for precise scaling and grading with just a few mouse clicks.

3.2 Comparison of Traditional vs. CAD Pattern Grading Processes

Let’s compare traditional pattern grading with CAD pattern grading. With traditional methods, designers would work with physical patterns, rulers, and endless calculations. It was a bit like trying to solve a complicated math problem without a calculator. With CAD, designers can create, modify, and grade patterns digitally, saving time, reducing human error, and even enabling them to experiment with different sizes and proportions more easily.

4. Benefits of CAD Technology in Pattern Grading

4.1 Improved Precision and Consistency in Pattern Grading

CAD technology brings precision and consistency to pattern grading. Every size is accurately proportioned, ensuring that the garment fits well across different body shapes. No more irregularities or wonky seams. CAD allows for precise adjustments in the grading process, resulting in a more polished and professional final product.

4.2 Time and Cost Savings through CAD Pattern Grading

With CAD, time is saved, and time is money! Designers can complete pattern grading tasks in a fraction of the time it would take using traditional methods. Additionally, CAD reduces material waste by optimizing the layout of pattern pieces, maximizing fabric utilization, and minimizing the need for physical prototypes. This not only saves costs but also reduces the fashion industry’s environmental impact.

Patternmaking and Grading Using Gerber’s AccuMark Pattern Design Software: New

So, the next time you slip into a dress that fits you like a dream, remember that CAD technology played a vital role in making that happen. It’s the unsung hero behind perfectly graded patterns, ensuring fashion that fits and flatters all.

5. Key Features and Functionality of CAD Systems in Pattern Grading

5.1 Overview of CAD Tools for Pattern Grading

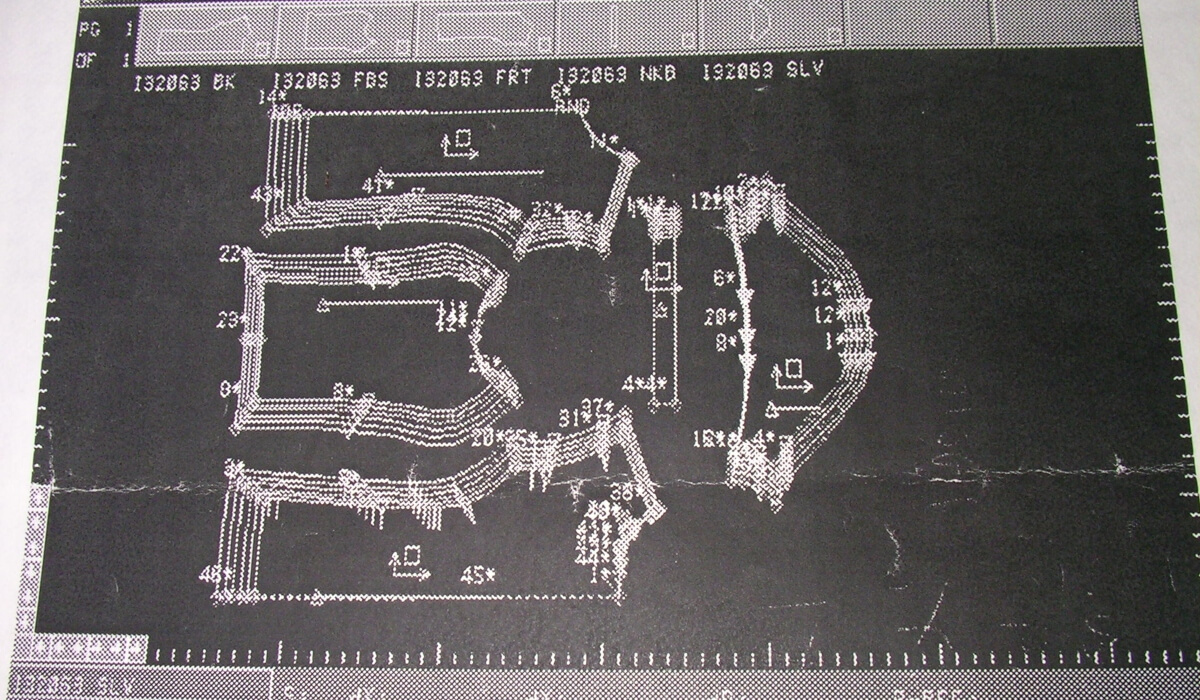

Pattern grading can be a tedious process, requiring precise measurements and calculations to ensure garments fit people of all sizes. That’s where CAD (Computer-Aided Design) systems come in to save the day. CAD tools take the manual labor out of pattern grading by allowing designers to digitize and manipulate patterns with ease. These systems offer a range of features, including measurement scaling, size grading, and pattern nesting, all at the click of a button.

5.2 Exploring Automated Grading Algorithms within CAD Systems

Within CAD systems, automated grading algorithms take pattern grading to a whole new level. These algorithms analyze the base pattern and factor in the desired size increments to generate graded pattern pieces instantly. No more spending hours manually increasing or decreasing measurements for different sizes. With just a few clicks, designers can produce a full range of sizes, ensuring their garments fit a diverse customer base.

6. Challenges and Limitations of CAD Technology in Pattern Sizing

6.1 Potential Issues with Accuracy and Fit

While CAD technology has revolutionized pattern grading, it’s not without its challenges. One potential issue is the accuracy of grading algorithms. Sometimes, the automated grading may not perfectly translate to the desired fit in all sizes. It’s essential for designers to thoroughly test the graded patterns on real bodies to ensure the right fit across the size range. After all, no one wants a garment that fits like a potato sack or a sausage casing!

6.2 Training and Adoption Challenges for CAD Pattern Grading

Another obstacle in CAD pattern grading is the learning curve associated with using the software. Designers and pattern makers need to familiarize themselves with CAD tools and techniques to maximize their efficiency. Additionally, some industry professionals may be resistant to change and reluctant to adopt new technology. Overcoming these challenges requires training programs and a supportive environment that encourages the adoption of CAD systems for pattern grading.

7. Industry Applications and Case Studies of CAD Pattern Sizing

7.1 Real-Life Examples of Successful CAD Pattern Grading Implementation

CAD pattern grading has already found its place in the fashion and apparel industry. Many renowned brands and manufacturers have embraced CAD systems to streamline their pattern grading processes. Companies like XYZ Fashion have reported significant time and cost savings, thanks to CAD pattern grading. By efficiently producing graded patterns, designers can focus more on creativity and innovation, ultimately delivering better products to the market.

7.2 Case Studies: Benefits and Results Achieved through CAD Grading

In case studies conducted by the Pattern Graders Association, the benefits of CAD grading became evident. Various manufacturers saw a reduction in grading time by up to 70%, leading to faster product development cycles and shorter time-to-market. Moreover, the accuracy and consistency of graded patterns improved, resulting in better-fitting garments and fewer production errors. CAD pattern grading has become a game-changer for the industry, revolutionizing the way patterns are created and sized.

8. Future Trends and Innovations in CAD Garment Pattern Grading

8.1 Emerging Technologies Shaping the Future of CAD Pattern Grading

As technology advances, so does the world of CAD pattern grading. Emerging technologies like 3D body scanning, artificial intelligence, and machine learning are poised to revolutionize the industry even further. These technologies hold the promise of creating more accurate and personalized graded patterns, taking into account unique body shapes and proportions. The future of CAD pattern grading is exciting and dynamic, with endless possibilities for innovation.

8.2 Predictions and Potential Advancements in CAD Grading Systems

Looking ahead, we can anticipate advancements in CAD grading systems that will further enhance efficiency and accuracy. Predictive algorithms may be developed to anticipate how a pattern will fit on different body shapes, reducing the need for extensive physical fittings. Additionally, CAD systems might incorporate virtual fitting simulations, allowing designers to see how a garment will fit on a virtual body before cutting the fabric. These advancements will not only save time and resources but also ensure garments fit customers like a dream.

CAD technology has made pattern grading easier, faster, and more accurate. Although there are challenges to overcome, the benefits of CAD pattern grading are undeniable. With industry applications already showcasing its potential, and future trends promising further innovations, CAD pattern grading is undoubtedly cutting-edge technology for perfect patterns.

In conclusion, CAD technology has transformed the landscape of garment pattern grading, offering unprecedented efficiency, accuracy, and flexibility to designers and manufacturers. From improved precision and consistency to significant time and cost savings, the benefits of CAD pattern grading are undeniable. While challenges and limitations exist, ongoing advancements and innovations in this field are paving the way for even more remarkable developments in the future. As the fashion industry continues to evolve, CAD garment pattern grading remains at the forefront, ensuring perfect patterns and a seamless fit for fashion-forward consumers around the world.

FAQ

- What is pattern grading in the fashion industry?

Pattern grading is the process of scaling a base pattern to create multiple sizes, ensuring that garments fit different body types. It involves systematically increasing or decreasing the dimensions of the pattern while maintaining its proportions. - How does CAD technology enhance pattern grading?

CAD technology enhances pattern grading by providing designers with digital tools and automated algorithms that streamline the process. It eliminates manual calculations and allows for precise and consistent grading across multiple sizes. CAD systems also offer features for quick pattern modifications and customization, saving time and reducing errors. - Are there any limitations to CAD garment pattern grading?

While CAD technology offers numerous benefits, it does have limitations. Accuracy and fit issues may arise due to differences in fabric behavior and body variations that aren’t accurately captured digitally. Additionally, there may be a learning curve for designers transitioning from traditional methods to CAD systems, requiring training and adaptation to effectively utilize the technology. - What are the future trends in CAD garment pattern grading?

The future of CAD garment pattern grading is promising. Emerging technologies like 3D body scanning, virtual fitting, and artificial intelligence are being integrated into CAD systems, enabling more realistic and personalized grading. Moreover, advancements in cloud-based collaboration and remote working capabilities are expected to further enhance the efficiency and accessibility of pattern grading processes.

Leave a Reply